The Company regards occupational health and safety as an important social responsibility and the foundation of sustainable operation, and provides employees with a safe and reliable working environment according to the occupational health and safety production guidelines of “safety first, prevention oriented, comprehensive management”.

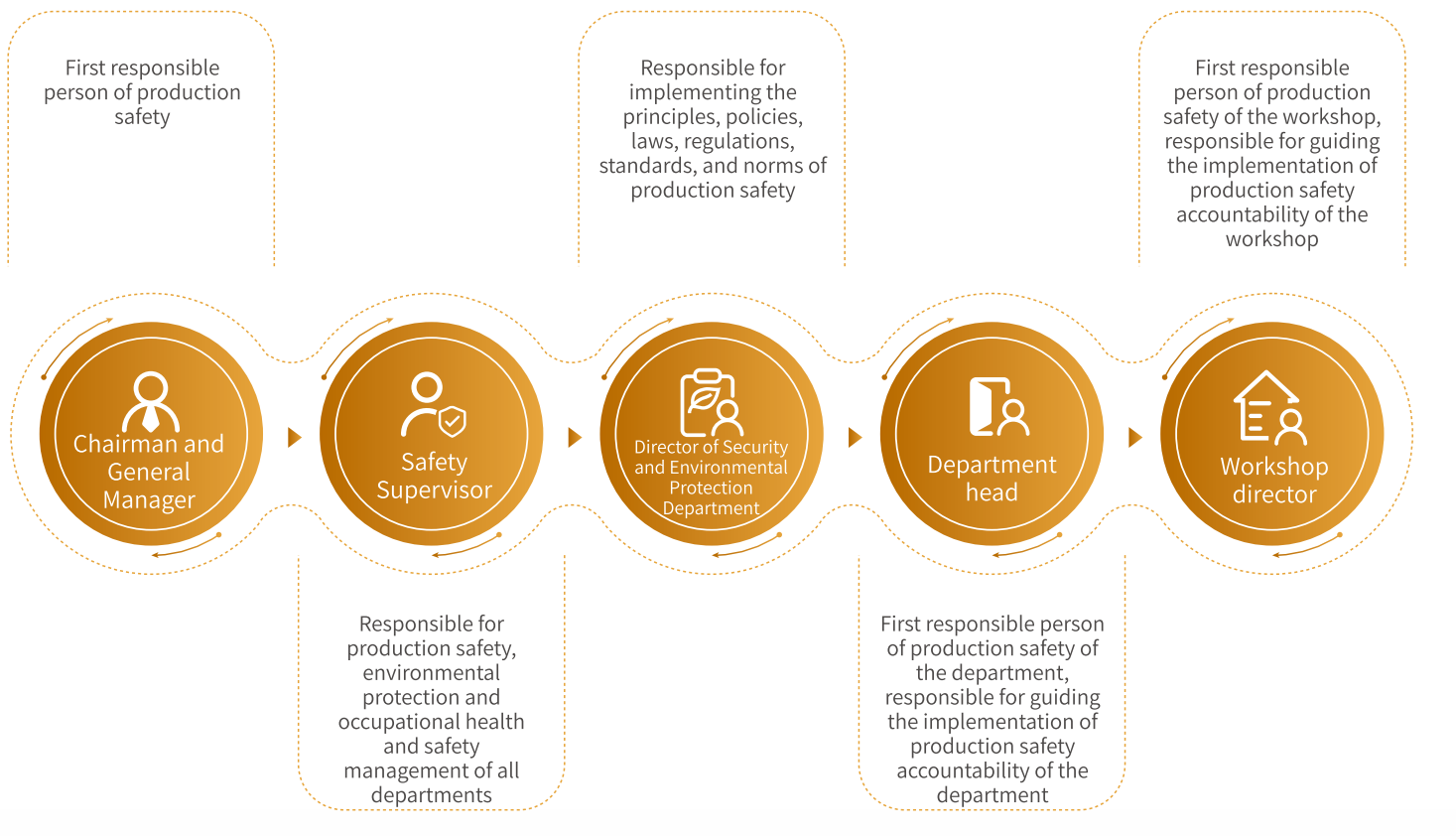

The Company sets up the Safety Production Committee, and makes it clear that the General Manager, the department heads, and the workshop directors shall act as the first responsible person for safety production at all levels. The Safety and Environmental Protection Office is responsible for coordinating with relevant departments to implement the all-staff safety production responsibility system jointly according to the safety production plan and requirements made by the Company.

The Company establishes the dual prevention working mechanism, investigates and rectifies hidden danger in high-incidence risk areas on a regular basis, implements the single-week “double investigation” mechanism for the hidden dangers such as leakage of hazardous chemicals, electric shock, and drowning, and makes timely rectification of any problem discovered. The department shall investigate the hidden dangers such as electricity safety and gas use in the accommodation areas of the Company and the construction organizations on a regular basis, and requests the team to report safety hazards in their workplaces every month, and encourages employees to pay attention to the hidden risk points around them.

Flow Chart for Safety Production Responsibility System of Zangge Potash Fertilizer

• In accordance with the “Work Safety Law of the People’s Republic of China”, the “Law on Prevention and Control of Occupational Diseases”, and the relevant specifications for safety production standardization, the Company has been introducing and improving the safety production related systems continuously, and completed the revision of the “Safety Production Management System of Golmud Zangge Potash Fertilizer Co., Ltd.” in 2022. Based on the safety production management system, the Company takes the measures such as safety agreement, performance assessment, and awareness promotion to protect the life safety of employees, and build a defense line of safety production.

• Zangge Mining improves the safety quality of its employees by various types of training; organizes the new employees to participate in on-boarding safety training, at which the executives of the Company will give instructions personally; offers the on-the-job training on a regular basis, releases the safety warning videos every day, holds safety knowledge competitions and safety seminars, and organizes the construction organizations to participate in special safety training, in order to further create a good atmosphere of safety production.

• In order to enhance the personnel’s emergency response capability to emergency safety incidents, the Company establishes the emergency organization system for the accidents at the Company and workshop level, and prepares and updates the emergency response plan on a regular basis, and organizes the production units to carry out the emergency rescue drills regularly, including cardiopulmonary resuscitation CPR drill, fire emergency drill, etc. In addition, the Company takes stock of and replenishes emergency resources, and conducts the effectiveness inspection and investigation of the on-site disposal scheme twice a year, so as to protect the life safety of employees effectively.