While changing and affecting the global ecosystem and natural environment, climate change also exerts deep impacts on global economic development and social consumption concepts. which in tum affects the survival and development of enterprises. Zangge Mining pays close attention to global climate change, and proactively identifies risks and opportunities brought out by climate change and makes strategies accordingly At the meantime, we keep optimizing our energy structure, and comprehensively enhancing our energy efficiency. and endeavor to reduce greenhouse gas emissions, to make positive contributions to the Paris Agreement Temperature Targets and China's carbon peaking and carbon neutrality goals.

Identification and management of climate risks and opportunities

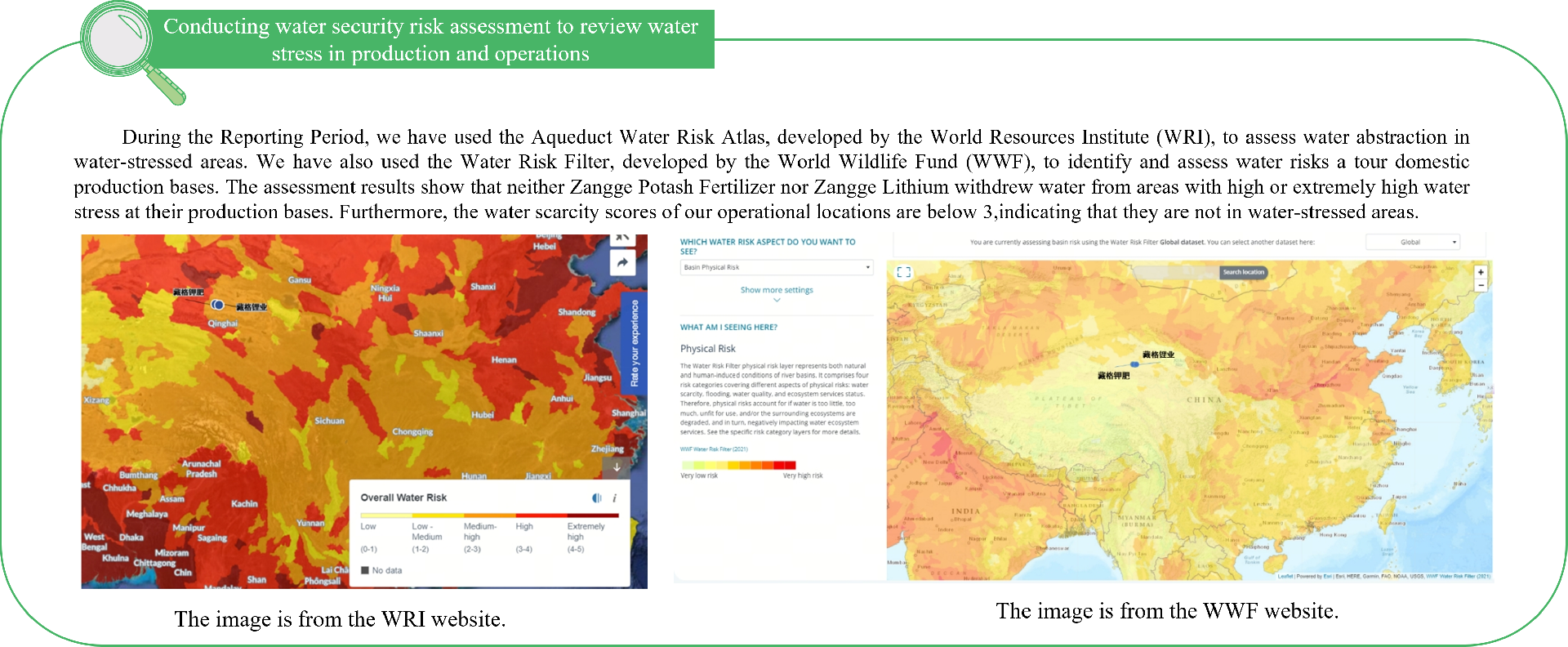

change on our production and operations. To strengthen our resilience against climate challenges and efficiently prevent and manage related risks, we have implemented a comprehensive top-down ESG management system. Within this system, the ESG and Sustainability Team plays a crucial role in identifying risks associated with climate change and collaborating closely with relevant departments and subsidiaries to formulate solutions and ensure their effective implementation. This year marked our first adoption of the Task Force on Climate-related Financial Disclosure (TCFD) Framework, Under this framework, we have systematically identified climate risks and opportunities and subsequently developed corresponding solutions with a particular focus on our major production sites.

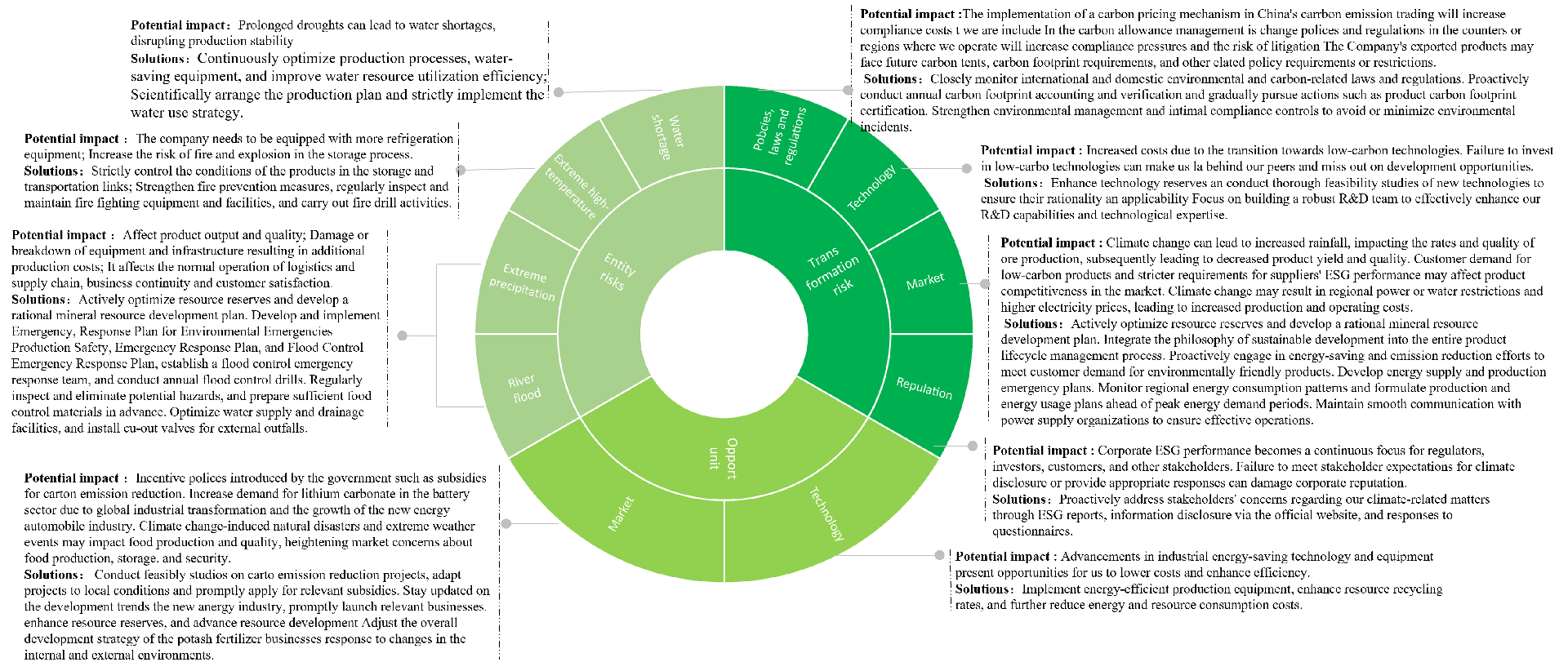

Physical risks:We performed a scenario analysis using two Representative Concentration Pathways(RCPs) adopted by the Intergovernmental Panel on Climate Change (IPCC)-RCP4.5 (low-carbon emissions scenario) and RCP8.5(high-carbon emissions scenario) Through this analysis, we have comprehensively identified our potential physical risks in the short term(by 2030), medium term (by 2050), and long term (by 2080). The results are presented in the table below.

Transition risks:In the context of the national strategy of "dual carbon goals" and the green transformation of global industries. extremal climate-related policies, technological innovations, market sentiment, and changing consumer preferences will pose potential compliance risks and cost pressures for all companies. Having identified and evaluated the transformation risks we face based on our business development, external policy adjustments, industry trends, and other factors, we have formulated preliminary corresponding solutions.

Energy management and clean technology opportunities

Zangge Mining strictly adheres to the Law of the People's Republic of China on Energy Conservation and other relevant regulations. We have developed and actively implemented several procedural documents, such as the Energy Management Regulations, Energy Performance Parameter Control Procedure, and Energy Manual, and effectively established an energy management system under ISO 50001. During the Reporting Period, both Zangge Potash Fertilizer and Zangge Lithium achieved the ISO 50001 energy management system certification.

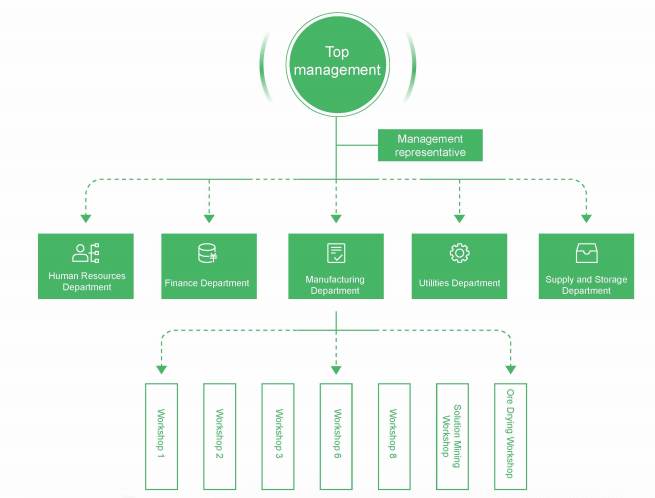

We place great importance on energy management and have established a comprehensive three-tier system consisting of the Company, departments (workshops), and workgroups. This network ensures that everyone within the Company is involved in and committed to our energy management efforts. Additionally, the Company has established an energy management leading group, headed by the General Manager. Responsible for overseeing energy management and making decisions related to energy use.

Organizational structure of energy management

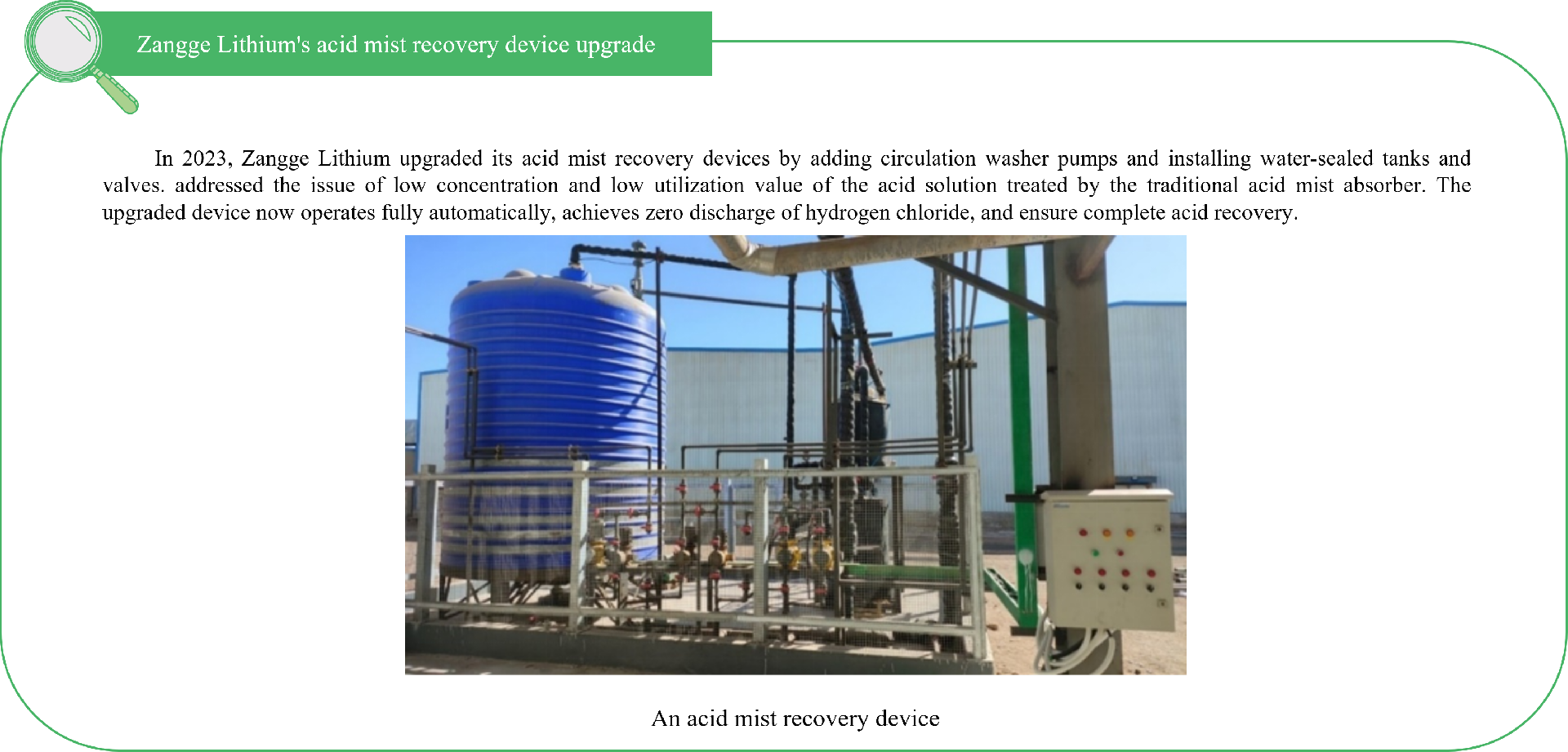

Energy Management Actions:Actively implementing energy management actions is crucial for responding to climate change and promoting transformation towards low-carbon development During the Reporting Period, Zangge Mining has strengthened energy management and diligently promoted the effective and detailed implementation of various energy management actions.

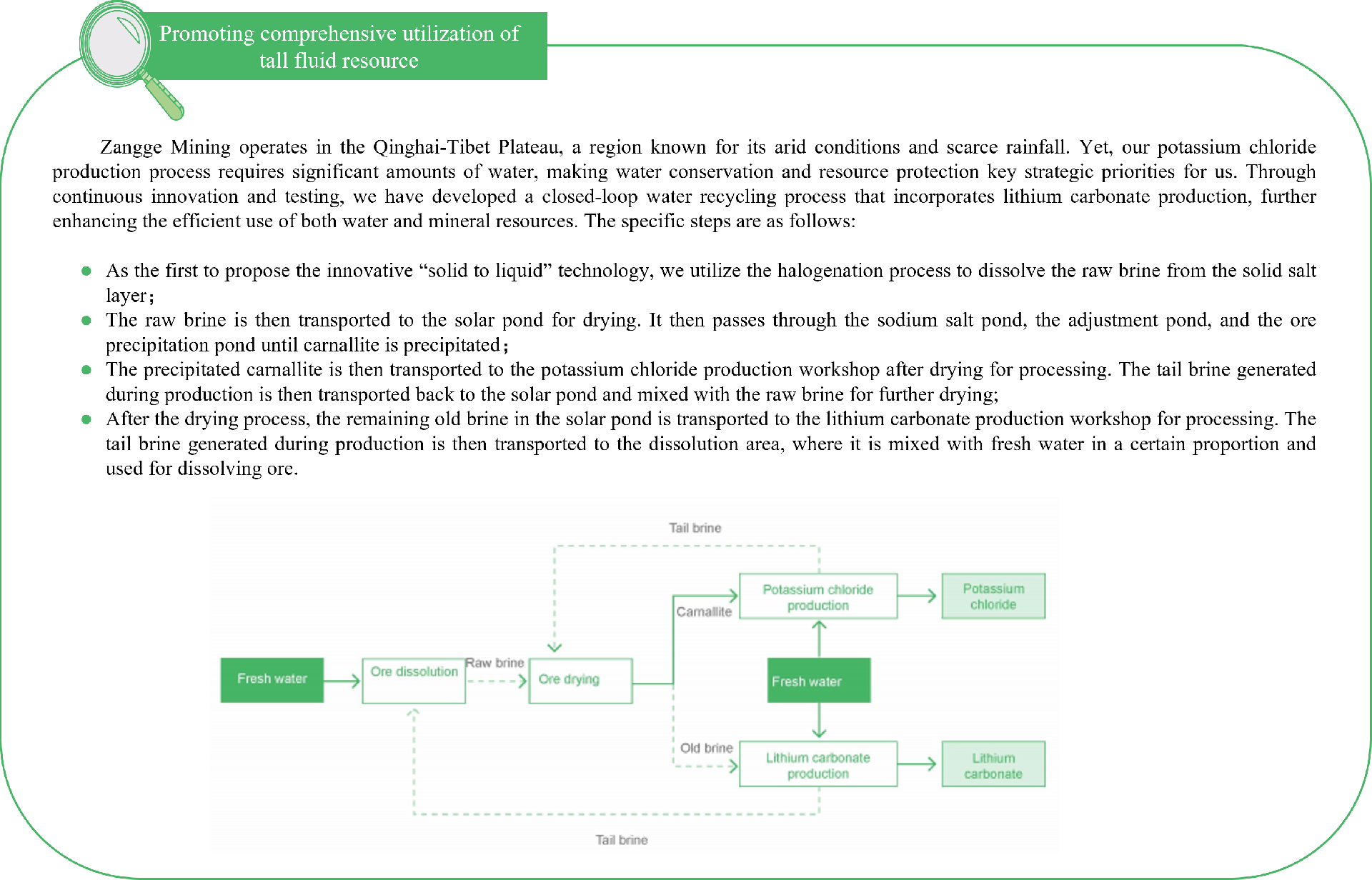

Clean technology opportunities:Zangge Mining is dedicated to the continuous exploration of clean technology and energy efficiency opportunities. Since identifying global energy transition opportunities in 2018, the Company has built new lithium carbonate production line, using tai brine from potash production as raw material for lithium extraction. This initiative has enhanced the comprehensive utilization of water and mineral resources. In 2023.we have enhanced our clean technology investment strategy by expanding our lithium resource reserves. We have achieved this through participation in industrial development funds, equity mergers and acquisitions, and other approaches.

Moreover, following an energy policy focused on "legal compliance, continuous improvement, innovative development, cost reduction, and efficiency enhancement", we actively explore energy conservation opportunities and optimize our energy structure through equipment upgrades, utilization of energy-saving technologies, and adoption of clean energy alternatives.